We collaborate with your team to tailor CMPs to tackle your most urgent asset integrity risks and prevent them from undermining your business, safety, and regulatory goals. We use our expertise to support your teams to move towards excellent maintenance behaviours and empower them with knowledge to ensure asset resilience for the long term.

At ICE, we know your equipment – and we know how to protect it. Check out our list of case studies to learn more about the work we do on sites like yours.

ICE adheres to rigorous internal practices related to sustainability and the safety of people and the environment. We believe in diversity of thought, compassion, and using business as a tool for greater good.

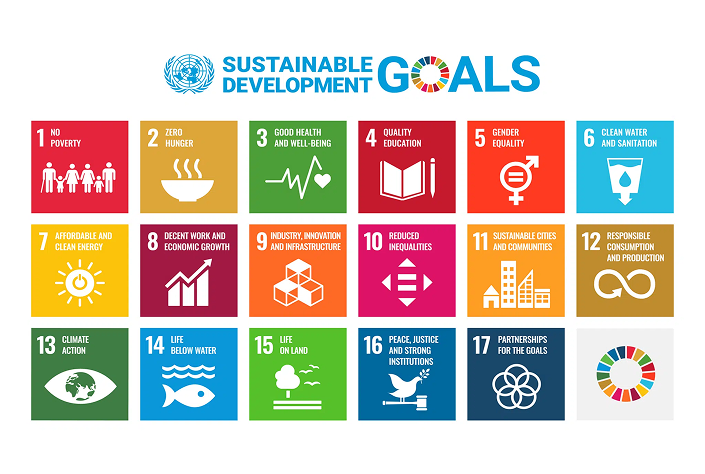

We know that looking after your physical assets directly impacts the drive toward sustainable operations. We are fully aligned with the UN Sustainable Development Goals and love to help our clients achieve the same!